Redesigned Linocut

Team: Trini Rogando, Elsa Bosemark, Talha Rao

Timeline: 4 weeks

Skills: Rapid prototyping (foam core, paper, dowels), RULA analysis, user feedback analysis, Likert data, Autodesk Fusion

Approach: Linoleum is a popular material for artists creating stamps. Cutting into linoleum requires a flexible tool, demanding both precision and force. To reduce hand strain and discomfort for these artists, my team focused on redesigning the blade handle.

Our process included multiple rounds of user testing, RULA analysis, and foam modeling of tool handles to measure ergonomic comfort.

Repetitive Motion Analysis

We began through talking through current users of the linocut to identify their grip patterns and usages, creating a task analysis and identifying points of highest strain.

Ideating, Defining, Prototyping

Group Design Parameters

Cuts the linoleum

Stable to maneuver

Good control over the blade so that cuts are exact

Flexibility for different grips

Uses same blade end

Comfortable to hold

Reduces pressure on fingers

Does not cramp hand after using it for a while

Not dangerous to use

Encourages correct hand and body posture

Works for different hand sizes

Ultimately, our 6 models had a variety of different shapes, suggested hand positions, and sizes.

Once we defined what our design parameters were due to physical constraint and tool function, the 3 of us each sketched 10 broad ideation brainstorms for ideation, then selected the strongest to physically model.

My drawings and foam models are below:

User Testing & Insight Gathering

With our 6 total foam models, we engaged in 3 rounds of user testing in a makerspace on campus, using the RULA national ergonomics worksheet and a visual hand/wrist pain indicator as a interview guide. gathering crucial insights:

Natural fit: Handles that matched natural hand curves felt most comfortable.

Grooves/curves: Well-placed indentations improved support and control.

Ergonomics: Even pressure and a healthy wrist angle were essential, with clear orientation.

Visibility: Users valued being able to see their work surface without hand/tool obstruction.

Leverage/precision: Awkward wrist motions or forced grips reduced control, and users valued feeling “close to the work”.

From these insights, my teammate Elsa created a matrix of two parameters of indicated interest to users:

Finger vs. Palm vs. Purlicue support

Grip angle (affecting control and finger positioning)

We then modeled 6 of these new iterated concepts - below are my foam models:

drawn by Elsa Bosemark

Data-Driven User Testing

For our second round of user testing, we developed a Likert survey to quantitatively determine which of our designs were the strongest, and administered it for each of our 6 new models.

Specific Evaluation Points

Tool size fit in hand

Angle comfort

Control of blade

Discomfort/pain points

Final Model

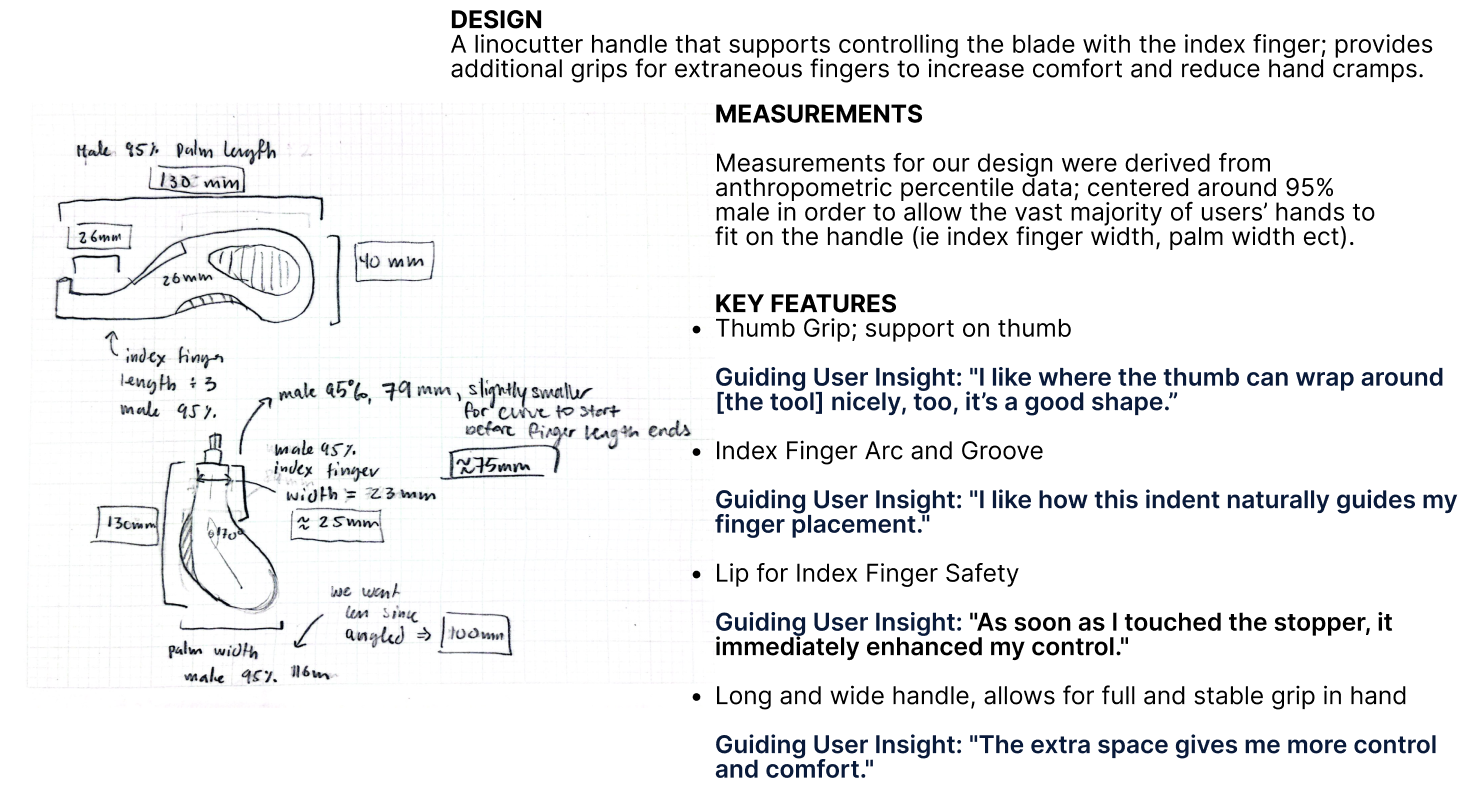

We developed measurements from the anthropometric table after devising our final design.

My CAD rendition of the design is below: